Email: manager@pefct.com

Whatsapp: +86 18561832088

Email: manager@pefct.com

Whatsapp: +86 18561832088

All of your questions about our egg tray machine or paper making machine will be replied in 24 hours.

One stop service to you for your paper pulp products production project (Project pre-analysis, paper pulp product making machine’s production, paper egg tray or paper machines installation).

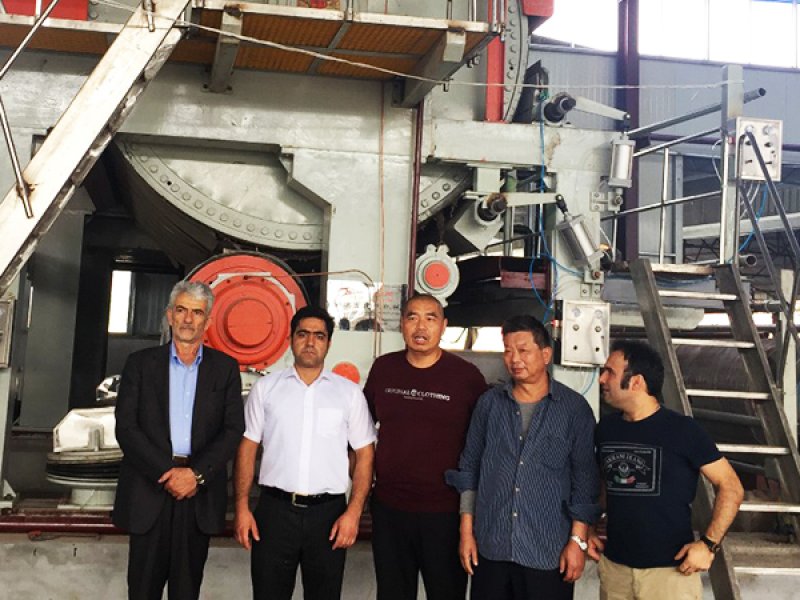

Engineers from China India Egypt will provide the machines following installation and training, reliable spare parts supply and technical support online.

Automatic paper pulp egg tray making machine

1. Rotary drum design, energy saving drive motor, low power consumption

2. High precision divider gearbox from Taiwan, International brand bearing, long life span

3. Stainless steel pulp tank, stainless steel pulp pipe, stainless steel machine cover

4. Aluminum forming molds can be customized as your egg tray or paper trays samples

5. Easy to change the forming molds, you can make different shape paper pulp packing trays by quick changing molds

6. 4 sides, 8 sides and 12 sides rotary drum design will different production capacities are optional

7. Brick drying oven, single or multi-layers metal dryer oven can be matched, various heat source (thermal oil, steam, natural gas, diesel oil, coal etc)

Model | R2000 | R3000 | R4000 | R4500 | R5000 | R6000 | R7000 |

Sides | 3*4 | 4*4 | 4*5 | 4*8 | 5*8 | 6*8 | 5*12 |

Molds Qty (PCS) | 12 | 16 | 20 | 32 | 40 | 48 | 60 |

Working Speed | 10-15 drops/min | 15-22 drops/min | 17-20 drops/min | ||||

Production Capacity (pieces/hour) | 2000-2500 | 2500-3500 | 3500-4200 | 4000-4500 | 5000-5500 | 6000-7000 | 5500-6500 |

Power Consumption | 57KW | 60KW | 75KW | 135KW | 147KW | 165KW | 175KW |

Water Consumption | 455kgs/H | 550kgs/H | 730kgs/H | 780kgs/H | 980kgs/H | 1150kgs/H | 1050kgs/H |

Waste Paper Consumption | 175kgs/H | 210kgs/H | 280kgs/H | 315kgs/H | 420kgs/H | 490kgs/H | 420kgs/H |

Waste paper old boxes as raw material, water is recycling, no pollution to environment | |||||||

Drying method: sunshine, brick drying oven, single or multi-layer metal dryer | |||||||

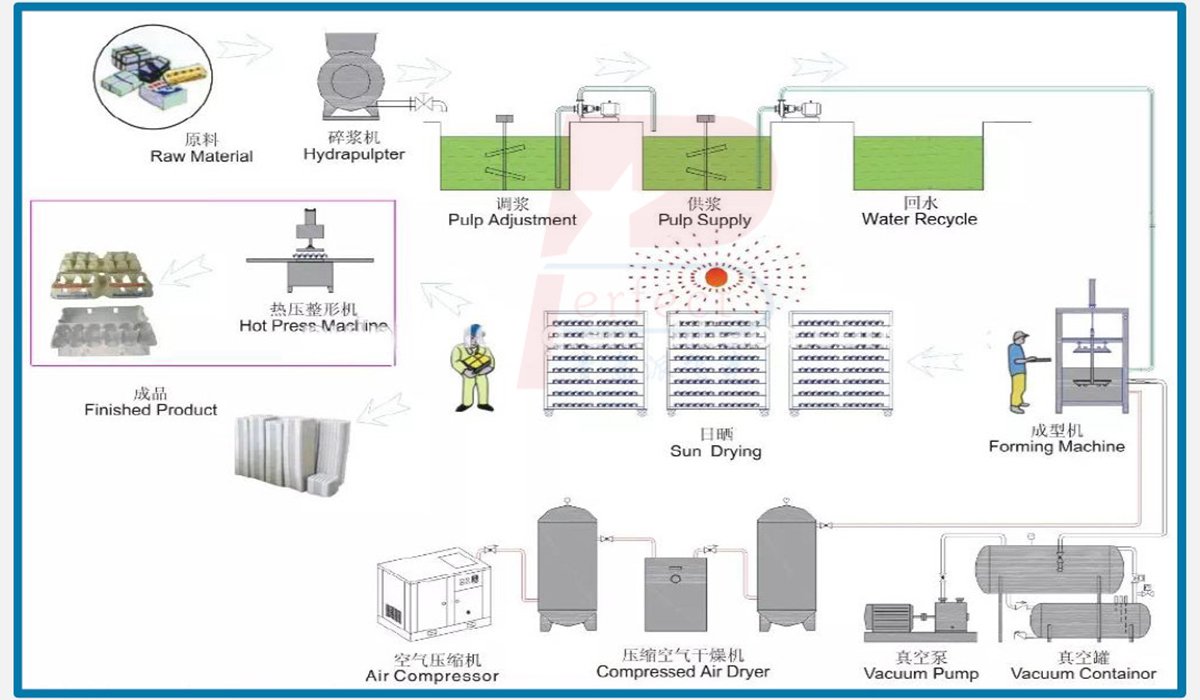

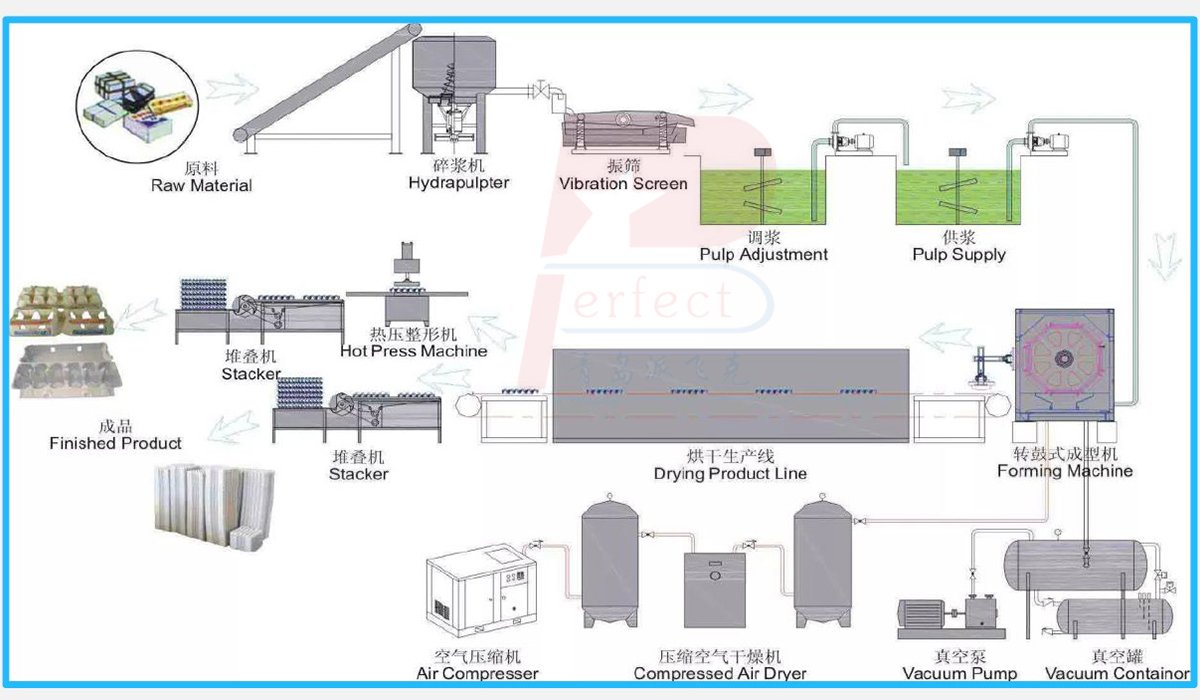

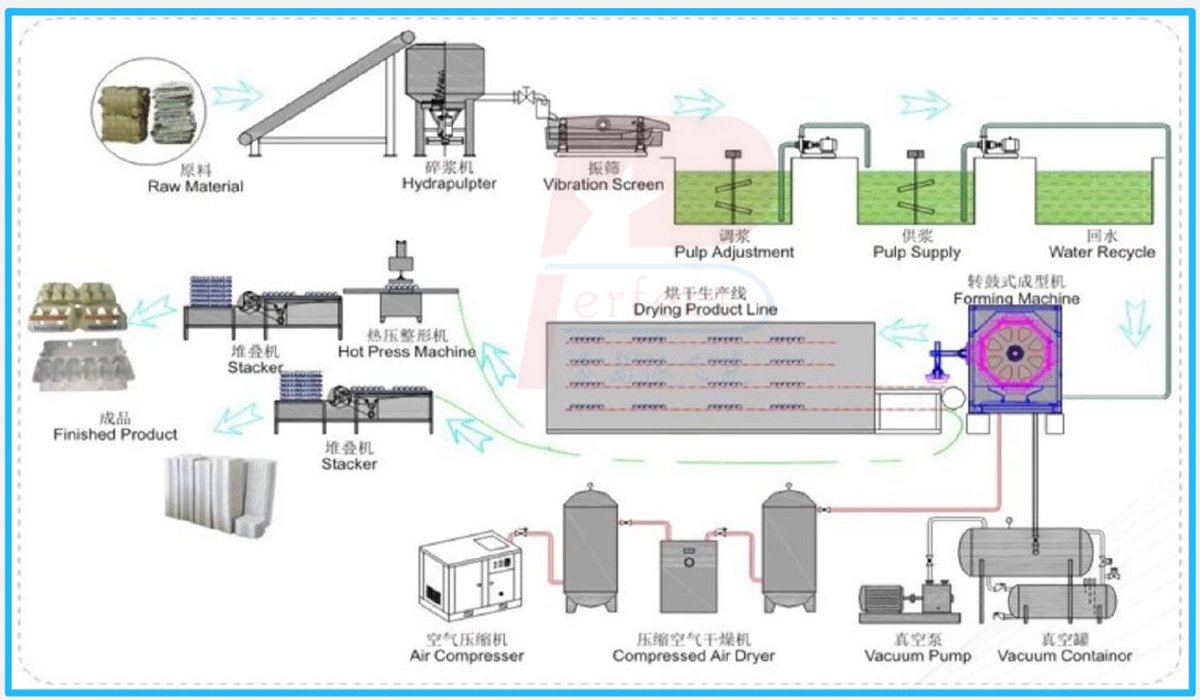

There are 4 steps for egg trays making from waste paper: pulp making, molding, drying, and packaging

Feed waste paper old boxes into hydra-pulper to beat it into pulp. Then store the pulp in the pulp pool.

Paper pulp molding machine form the paper egg trays with the assist of vacuum pump and air compressor, output wet trays.

You can choose natural sunshine drying, brick drying oven, or metal dryer oven to dry the wet egg trays.

Large scale production line always employs an automatic packing system, including automatic counter, packer, hot press machine and hot press molds etc.

More than 20 years production history for paper pulp molding machines making since 2001

1. More than 20 years production history for paper pulp molding machines making since 2001, we are a high-tech enterprise that designs, produces and sells paper making machinery and pulping equipment. Mainly produces various types of egg tray making machines, tissue paper machines, craft paper making machines other series of paper pulp machine equipment.

2. In China market, our egg tray making machines occupy more than 55% market, tissue paper machine and craft paper machines 35% domestic market; For abroad market, our paper pulp molding machines already been exported to more than 75 countries mainly in Africa, Asia, Middle East, South America and East Europe.

3. Strong production capacity and reliable technical support team, more than 45000 square meters production workshop, 4 sets advanced CNC parts manufacturing machines and 2 setslaser metal cutting machines, more than 150 skilled workers, 19 develop engineers, 28 after sales engineers for installation from China, India, Egypt.

4. Super class after-sales service, all of after sales installation service engineers are with rich of domestic and abroad installation experience, they will provide you the most professional service and training.

years, Production History

Million USD, Sales Amount

Engineers, Professional

Countries, Worldwide

Firstly, we are an experienced egg tray machine manufacturer and exporter. We have more than 65 years production history in this industry and in China domestic market, our machines occupied around 65% market, and we have helped more than 130 egg trays paper pulp trays manufacturers successfully all over the world.

Secondly, We have our own factory, and main metal parts for the machines are manufactured by ourself CNC center, where you can come to visit us on site, this makes us can guarantee the machines quality a lot, and you can also visit our domestic client’s production sites to familiar our machine’s working well.

There is a professional team from pre-sales consulting, designer, engineers, sales, to after-sales service. Also, we have cooperated local engineers in many countries for easier local installation and service. And we have English, Spanish, Russian teams to serve the different countries clients from all over the world.